Welcome to Tilbury cement Works

Our flagship materials imports and manufacturing facility

Set in a prime location on the River Thames, our state-of-the-art facility marks a bold step forward in Holcim UK’s mission to make sustainable construction a reality.

At Tilbury, we’re transforming how building materials are made, moved and delivered. With a focus on innovation, agility and environmental responsibility, the terminal is set to become a key hub for Holcim UK’s cement product ranges.

Once operational, our advanced facility will manufacture and supply a diverse range of traditional and innovative products, including GGBS, ECOPlanet and other low carbon and circular cementitious materials.

QUALITY PRODUCTS AVAILABLE SOON!

Supplied from six loading heads and five weighbridges, our materials will be available 24/7 to collect or deliver across the South of England. We’ll be offering a range of materials including:

CEM I Cement

Ordinary Portland Cement (OPC) is a high strength cement suitable for a wide variety of applications. This CEM I 52,5N material is fully compliant with BS EN 197-1, and is manufactured to the highest quality standards to ensure material consistency.

CEM II Cement

Portland Limestone cement is perfect as a lower carbon cement replacement for OPC. This high

strength 52,5N CEM II/A-L is quality controlled to conform to BS EN 197-1. Its lighter grey colour makes it perfect for architectural projects, as well as for precast concrete, readymix, screed, mortar, render, grouts and volumetric production.

GGBS

Ideal for low carbon concrete production, we’ll be grinding Ground Granulated Blast Furnace Slag (GGBS) on site. GGBS - a by product from steel manufacturing - is a cement addition providing a perfect mix of environmental and performance benefits.

ECOPlanet® Cement

With 30% less carbon than any other Portland cement currently available in the UK, ECOPlanet® sulfate resistant cement offers the perfect combination of eco credentials and great performance, while being fully compliant with British Standards.

ECOCycle® Cement

As part of our commitment to drive circular construction across the UK, we’ll be introducing

ECOCycle® - an independently verified cement made with recycled construction demolition materials.

Tilbury Cement Works Prospectus

This digital guide showcases our amazing build journey at Tilbury docks, our approach to sustainability and new product innovation, and an overview of the advanced technology used on site.

Download your copy today!

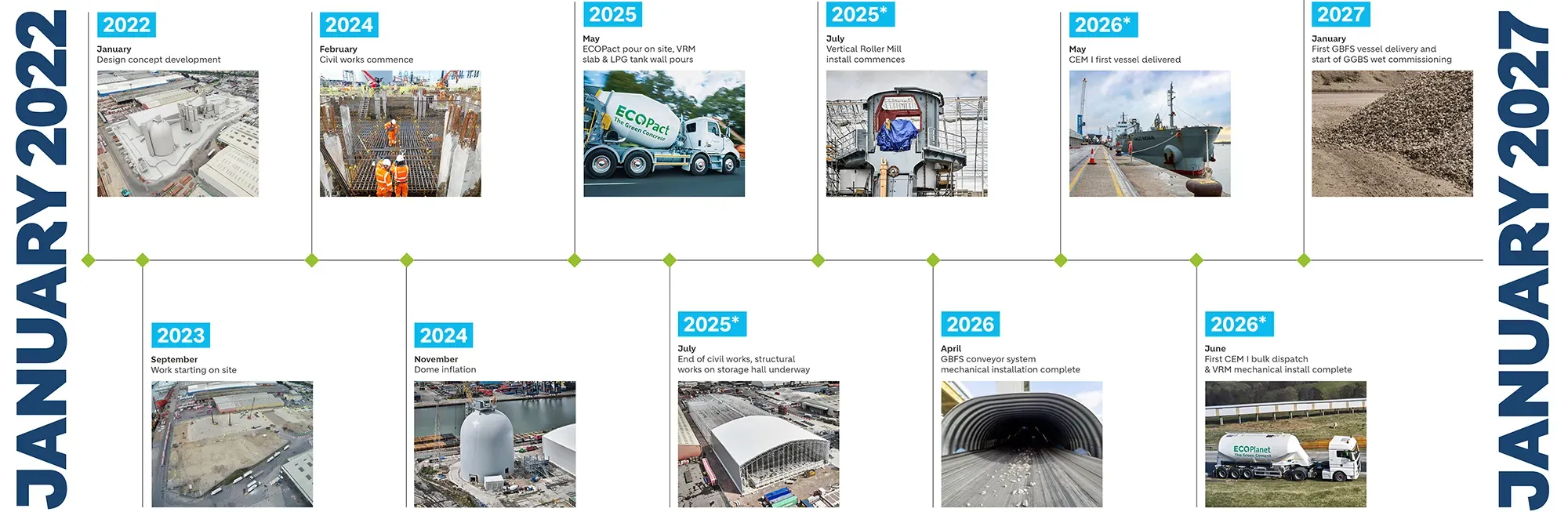

Our Build Journey

Starting on site in September 2023, Tilbury is due for final completion on site in 2026, ready to serve customers across the region and beyond.

Inside the Build

Greener from substructure to skyline. From the outset, every element of the terminal’s development has been shaped by circular principles and carbon conscious choices. Over 25,000 m3 of concrete from the original site has been recycled and reused, alongside 10,000 tonnes of recycled asphalt plannings incorporated into new surfacing solutions.

Plus, nearly 20,000 tonnes of excavated material has been recycled through our waste management business.

During construction, we’ve used a broad range of lower carbon materials from our own portfolio - including ECOPact ready-mix concrete, precast components, recycled aggregates, and reclaimed asphalt - ensuring our sustainability ambitions are reflected not just in the products we’ll deliver, but in the way we’ve built the site itself.

Tilbury doesn’t just support sustainable construction - it’s built on it.

Contact Us

If you’d like to know more, get some free product samples, or even the site, please reach out, we’d be delighted to welcome you to Tilbury or provide more product information. Our local area manager Scott Connelly is on scott.connelly@holcim.co.uk or 07484 480764.

Alternatively, complete the short enquiry form below and we will get back to you as soon as we can.